TAL Process Chillers

Precision Cooling, Engineered for Excellence

Vital Technik presents its TAL Process Chillers, a range of high-precision, energy-efficient industrial chillers.

These products stand out for their exceptional reliability, customisable options, and innovative features like outdoor kits, negative cold options, and microchannel condensers.

Designed for a variety of industrial applications, they offer cooling precision, non-ferrous liquid circuits, and a compact layout, ensuring superior performance and versatility in cooling solutions.

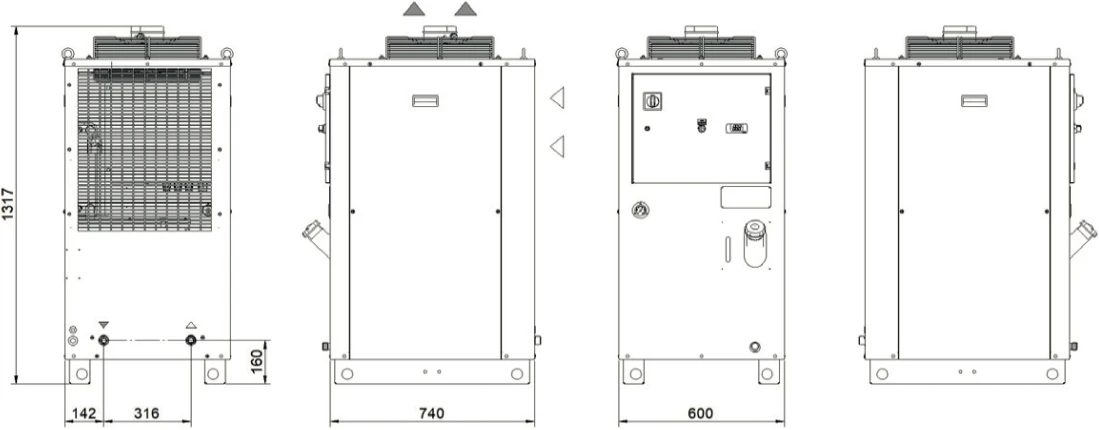

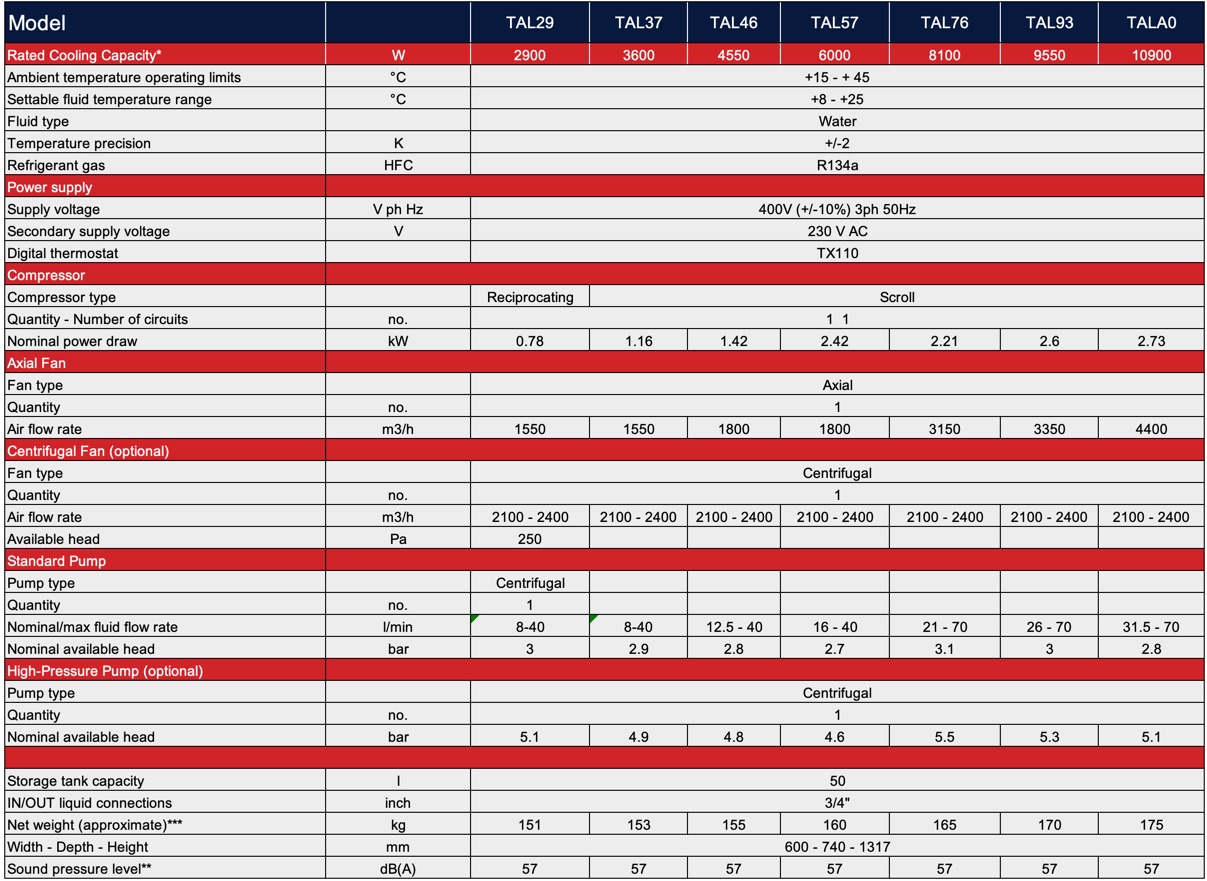

TAL29÷A0 Size 1 Three-phase

Industrial water chillers

COOLING CAPACITY:

2900 – 3600 – 4550 – 6000 – 8100 – 9550 – 10900 W

STRUCTURE

In powder-coated steel sheet, RAL 7035 textured finish. Easily removed panels

COMPRESSOR

Hermetic Reciprocating or Scroll compressor, cooled by the refrigerant, complete with thermal cut-out.

REFRIGERATION CIRCUIT

Complete with charging port, drier filter, expansion or thermostatic valve, high-pressure pressure switch, R134a refrigerant.

EVAPORATOR

Brazed stainless-steel plate model.

AIR CONDENSER

Microchannel condensing coil, complete with safety grille.

AXIAL FAN

Axial fan, complete with thermal cut-out and safety grille.

LIQUID CIRCUIT

Non-ferrous liquid circuit composed of centrifugal electric pump, storage tank made of plastic material complete with integrated visual level indicator, 0-10 bar pressure gauge, protective flow switch, regulation sensor.

ELECTRICAL PANEL

With main disconnect switch, relay motor protection, phase sequence relays.

MANAGEMENT & CONTROL

The TX110 control unit manages the chiller’s operation, providing warnings including high/low temperature alarms and a general serious fault alarm, with the display indicating if this refers to the refrigeration or liquid circuit. An on-off contact allows the machine to be switched on remotely (pump included). Control disconnect switch for switching on the machine.

PAINT/COATING

Standard colour: RAL 7035 textured.

MAIN OPTIONS

BA – Mechanical bypass valve protecting the pump LTA – Operation at low ambient temperatures

FP – Polyurethane air filter

RU – Castors

TD – Differential fluid temperature management (two sensors) BGC – Hot gas bypass for +/- 1 K temperature precision

BGP – Hot gas bypass for +/- 0.5 K temperature precision

LS – Liquid circuit for laser application

UL1 – Electrical panel and UL-certified components

LTW – Water temperature range -10/+5 °C

– HIGH-pressure pump version “H” – 5 bar, version “R” – 7 bar.

– Outdoor installation options

Dimensions

* Data relates to operation under the following conditions: inlet/outlet temp. 20/15°C, water without glycol, ambient temperature 32°C.

** Sound pressure level, measured in a free parallelepiped field at a distance of 1 m, per ISO 3746.

*** Weight includes pallets and packaging (where provided for), with refrigerant charge, storage tank empty, axial fans.

The electrical data refer to cos φ = 0.8.

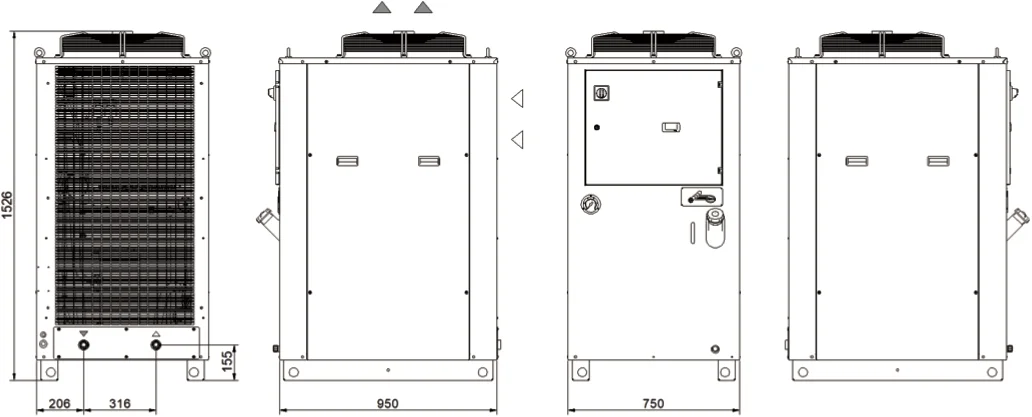

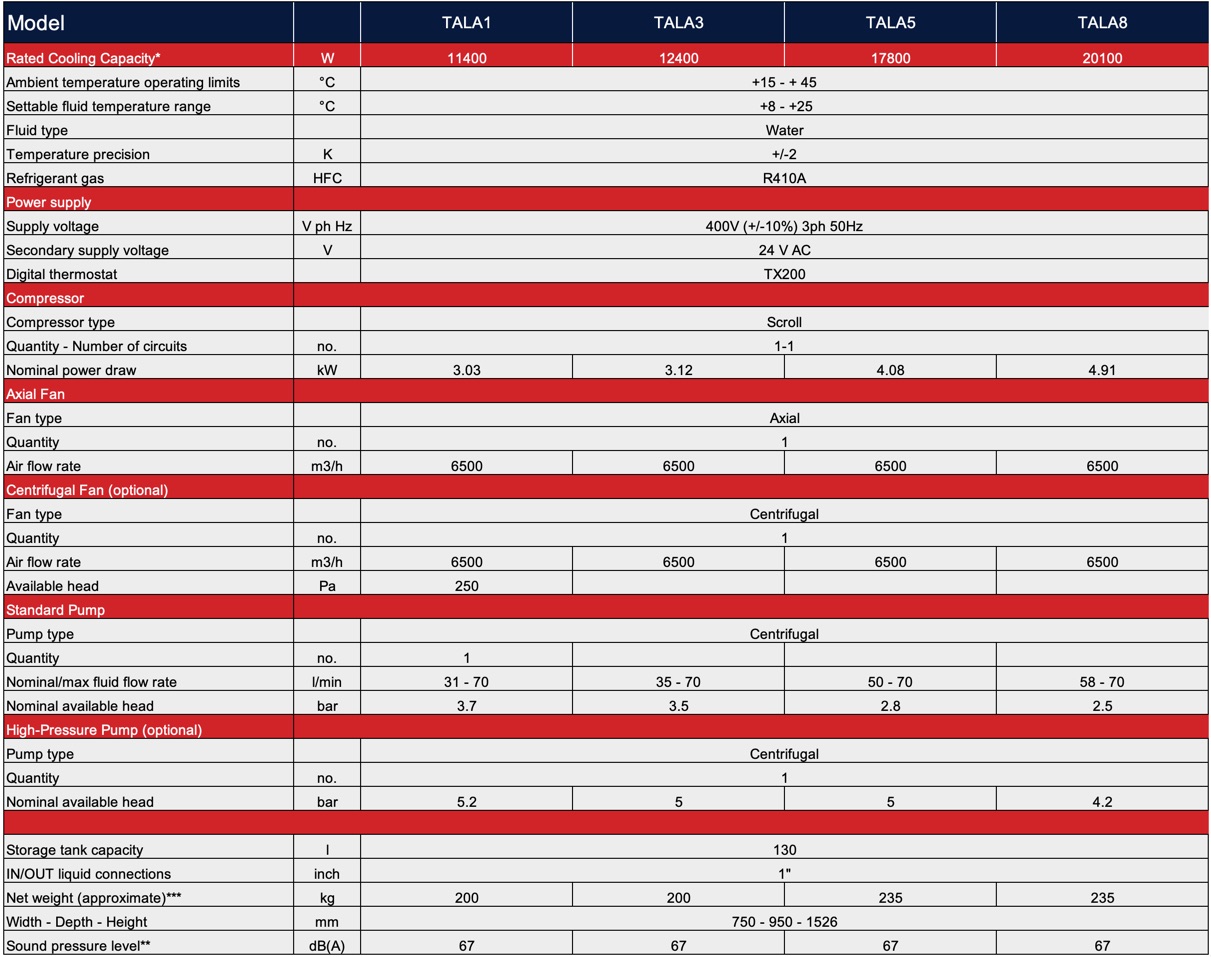

TALA1-A8 Size 2

Industrial water chillers

COOLING CAPACITY:

11400 – 12400 – 17800 – 20100 W

STRUCTURE

In powder-coated steel sheet, RAL 7035 textured finish. Easily removed panels

COMPRESSOR

Hermetic scroll compressor, cooled by the refrigerant, complete with thermal cut-out.

REFRIGERATION CIRCUIT

Complete with charging port, liquid receiver, drier filter, thermostatic valve, high- and low-pressure pressure switch, R410A refrigerant.

EVAPORATOR

Brazed stainless-steel plate model.

AIR CONDENSER

Microchannel condensing coil, complete with safety grille.

AXIAL FAN

Axial fan, complete with thermal cut-out and safety grille.

LIQUID CIRCUIT

Non-ferrous liquid circuit composed of stainless-steel centrifugal pump, plastic storage tank complete with visual level indicator, electrical level, 0-10 bar pressure gauge, differential pressure switch protecting the water flow, regulation sensor.

ELECTRICAL PANEL

With main disconnect switch, relay motor protection, phase sequence relays.

MANAGEMENT & CONTROL

The TX200 control unit manages the operation of the chiller and provides complete operator alarm diagnostics. An on-off contact allows the machine to be switched on remotely. Illuminated control selector. Possibility of remote display for machine regulation.

PAINT/COATING

Standard colour: RAL 7035 textured.

MAIN ACCESSORIES

BA – Mechanical bypass valve protecting the pump

FL – Flow switch with alarm contact

FP – Polyurethane air filter

RU – Castors

TD – Differential fluid temperature management (two sensors) BGC – Hot gas bypass for +/- 1 K temperature precision

LS – Liquid circuit for laser application

HP/HS – Harting type connectors

– HIGH-pressure pump version “H” – 5 bar, version “R” – 7 bar.

– Outdoor installation optionals

Dimensions

* Data relating to operation under the following conditions: intake/outlet temperature 20/15°C, water without glycol, ambient temperature 32°C.

**Sound pressure level measured in a free parallelepiped field at a distance of 1 m from the machine per ISO 3746.

*** Weight includes pallets and packaging (where provided for), with refrigerant charge, storage tank empty, axial fans.

**** The electrical data refer to cos φ = 0.8.

However, due to our continuous development and improvement of our products, all information is subject to change without notice.

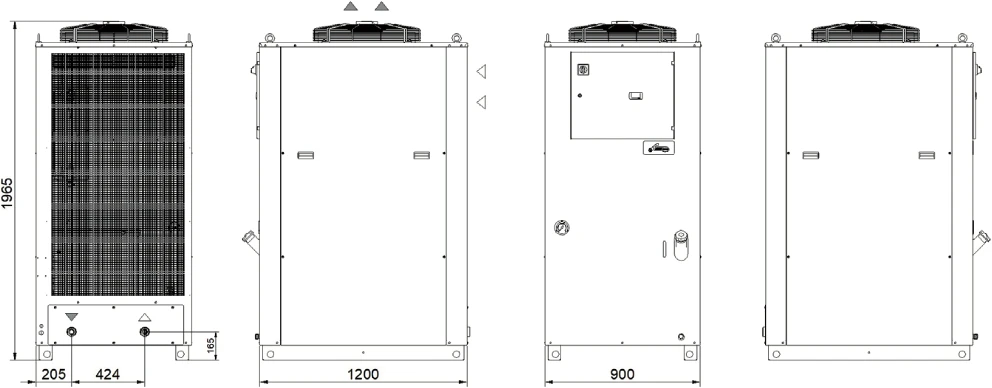

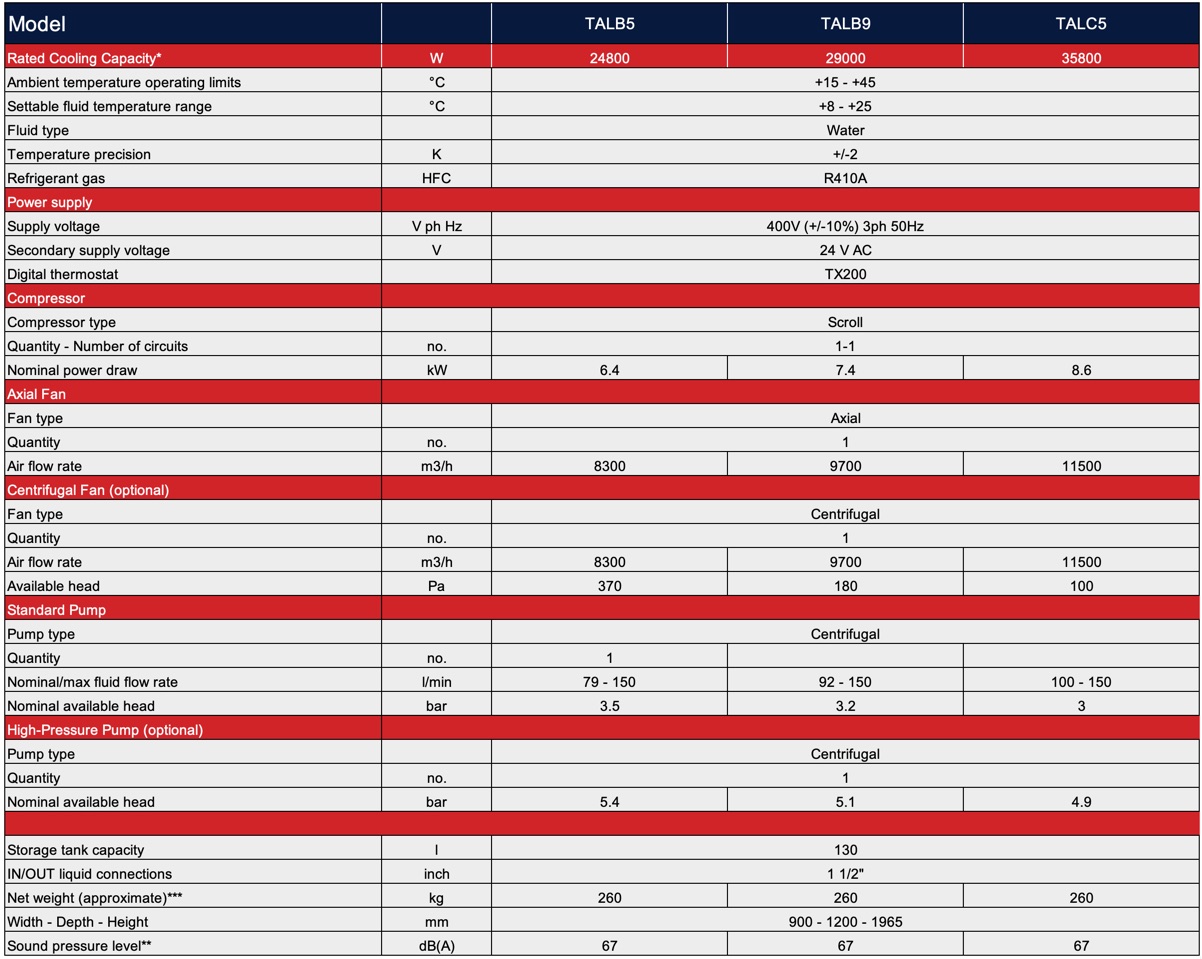

TALB5-C5 Size 3

Industrial water chillers

COOLING CAPACITY:

24800 – 29000 – 35800 W

STRUCTURE

In powder-coated steel sheet, RAL 7035 textured finish. Easily removed panels

COMPRESSOR

Hermetic scroll compressor, cooled by the refrigerant, complete with thermal cut-out.

REFRIGERATION CIRCUIT

Complete with charging port, liquid receiver, drier filter, thermostatic valve, high- and low-pressure pressure switch, R410A refrigerant.

EVAPORATOR

Brazed stainless-steel plate model.

AIR CONDENSER

Microchannel condensing coil, complete with safety grille.

AXIAL FAN

Axial fan, complete with thermal cut-out and safety grille.

LIQUID CIRCUIT

Non-ferrous liquid circuit composed of stainless-steel centrifugal pump, plastic storage tank complete with visual level indicator, electrical level, 0-10 bar pressure gauge, differential pressure switch protecting the water flow, automatic by-pass and regulation sensor.

ELECTRICAL PANEL

With main disconnect switch, relay motor protection, phase sequence relays.

MANAGEMENT & CONTROL

The TX200 control unit manages the operation of the chiller and provides complete operator alarm diagnostics. An on-off contact allows the machine to be switched on remotely. Illuminated control selector. Possibility of remote display for machine regulation.

PAINT/COATING

Standard colour: RAL 7035 textured.

MAIN ACCESSORIES

FL – Flow switch with alarm contact FP – Polyurethane air filter

RU – Castors

TD – Differential fluid temperature management (two sensors) BGC – Hot gas bypass for +/- 1 K temperature precision

LS – Liquid circuit for laser application

HP/HS – Harting type connectors

– HIGH-pressure pump version “H” – 5 bar, version “R” – 7 bar.

– Outdoor installation optionals

Dimensions

* Data relating to operation under the following conditions: intake/outlet temperature 20/15°C, water without glycol, ambient temperature 32°C.

** Sound pressure level measured in a free parallelepiped field at a distance of 1 m from the machine per ISO 3746.

*** Weight includes pallets and packaging (where provided for), with refrigerant charge, storage tank empty, axial fans.

**** The electrical data refer to cos φ = 0.8.

However, due to our continuous development and improvement of our products, all information is subject to change without notice.

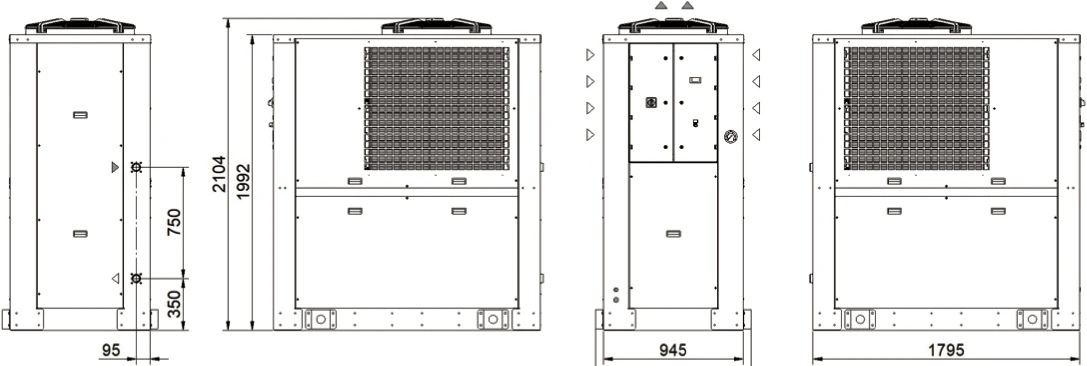

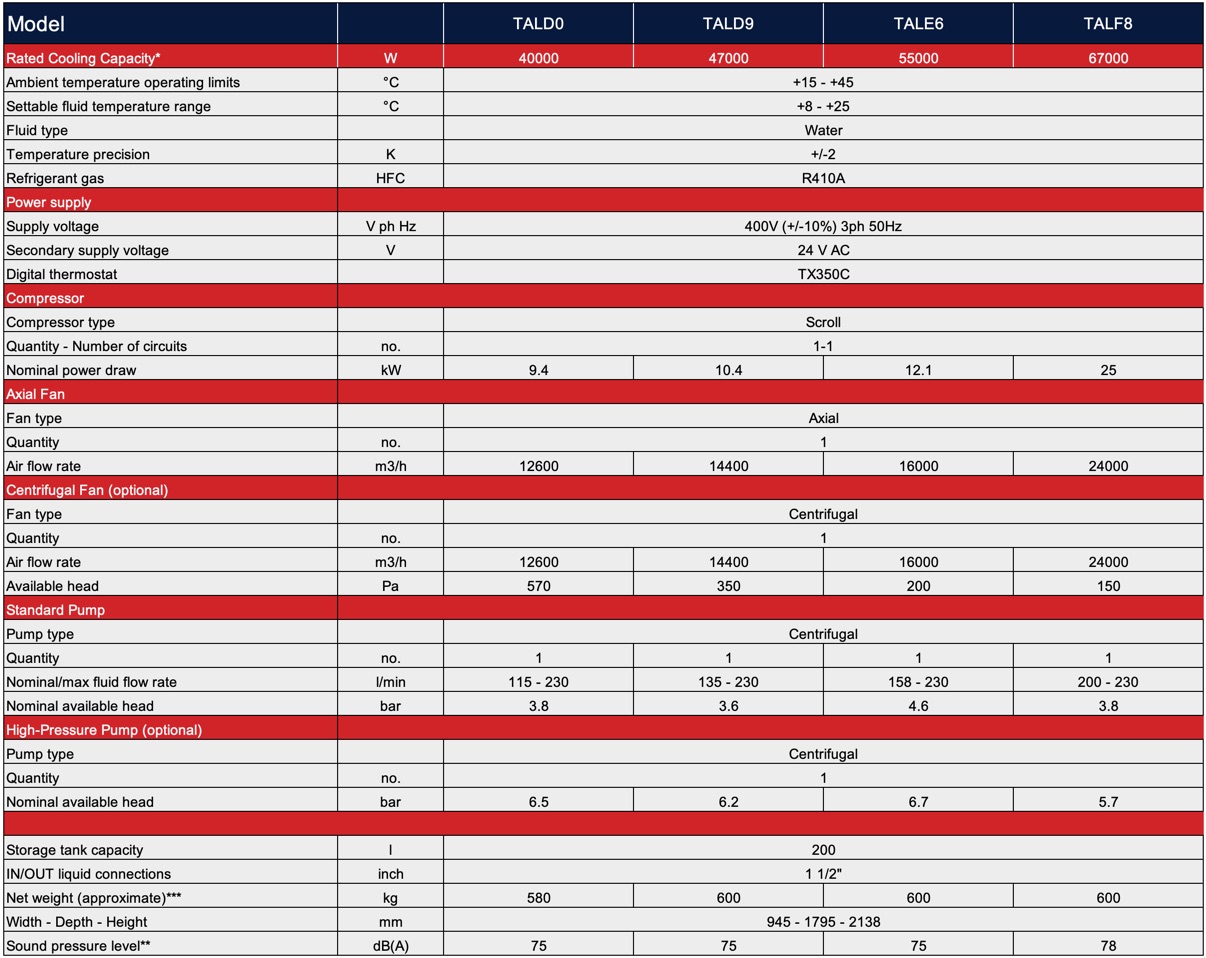

TALD0-F8 Size 4

Industrial water chillers

COOLING CAPACITY:

40000 – 47000 – 55000 – 67000 W

STRUCTURE

In powder-coated steel sheet, RAL 7035 textured finish. Easily removed panels

COMPRESSOR

Hermetic scroll compressor, cooled by the refrigerant, complete with thermal cut-out.

REFRIGERATION CIRCUIT

Complete with charging port, liquid receiver, drier filter, thermostatic valve, high- and low-pressure pressure switch, R410A refrigerant. Optional 2-step cooling power regulation (standard on TALF8).

EVAPORATOR

Brazed stainless-steel plate model.

AIR CONDENSER

Microchannel condensing coil, complete with safety grille.

AXIAL FAN

Axial fan, complete with thermal cut-out and safety grille.

LIQUID CIRCUIT

Non-ferrous liquid circuit composed of stainless-steel centrifugal pump, plastic storage tank complete with drain valve, electrical level, 0-10 bar pressure gauge, differential pressure switch protecting the water flow, automatic by-pass and regulation sensor.

ELECTRICAL PANEL

With main disconnect switch, relay motor protection, phase sequence relays.

MANAGEMENT & CONTROL

The TX350C control unit manages the operation of the chiller and provides complete operator alarm diagnostics. An on-off contact allows the machine to be switched on remotely. Illuminated control selector. RS485 connection. Possibility of remote display for machine regulation.

PAINT/COATING

Standard colour: RAL 7035 textured.

MAIN ACCESSORIES

FL – Flow switch with alarm contact

HR – Fluid heating element

OM – Unit built for outdoor operation down to -10 °C ambient temp. OML – Unit built for outdoor operation down to -20 °C ambient temp. FP – Polyurethane air filter

TD – Differential fluid temperature management (two sensors) BGC – Hot gas bypass for +/- 1 K temperature precision

LS – Liquid circuit for laser application

– HIGH-pressure pump version “H” – 5 bar

Dimensions

* Data relating to operation under the following conditions: intake/outlet temperature 20/15°C, water without glycol, ambient temperature 32°C.

** Sound pressure level measured in a free parallelepiped field at a distance of 1 m from the machine per ISO 3746.

*** Weight includes pallets and packaging (where provided for), with refrigerant charge, storage tank empty, axial fans.

**** The electrical data refer to cos φ = 0.8.

However, due to our continuous development and improvement of our products, all information is subject to change without notice.

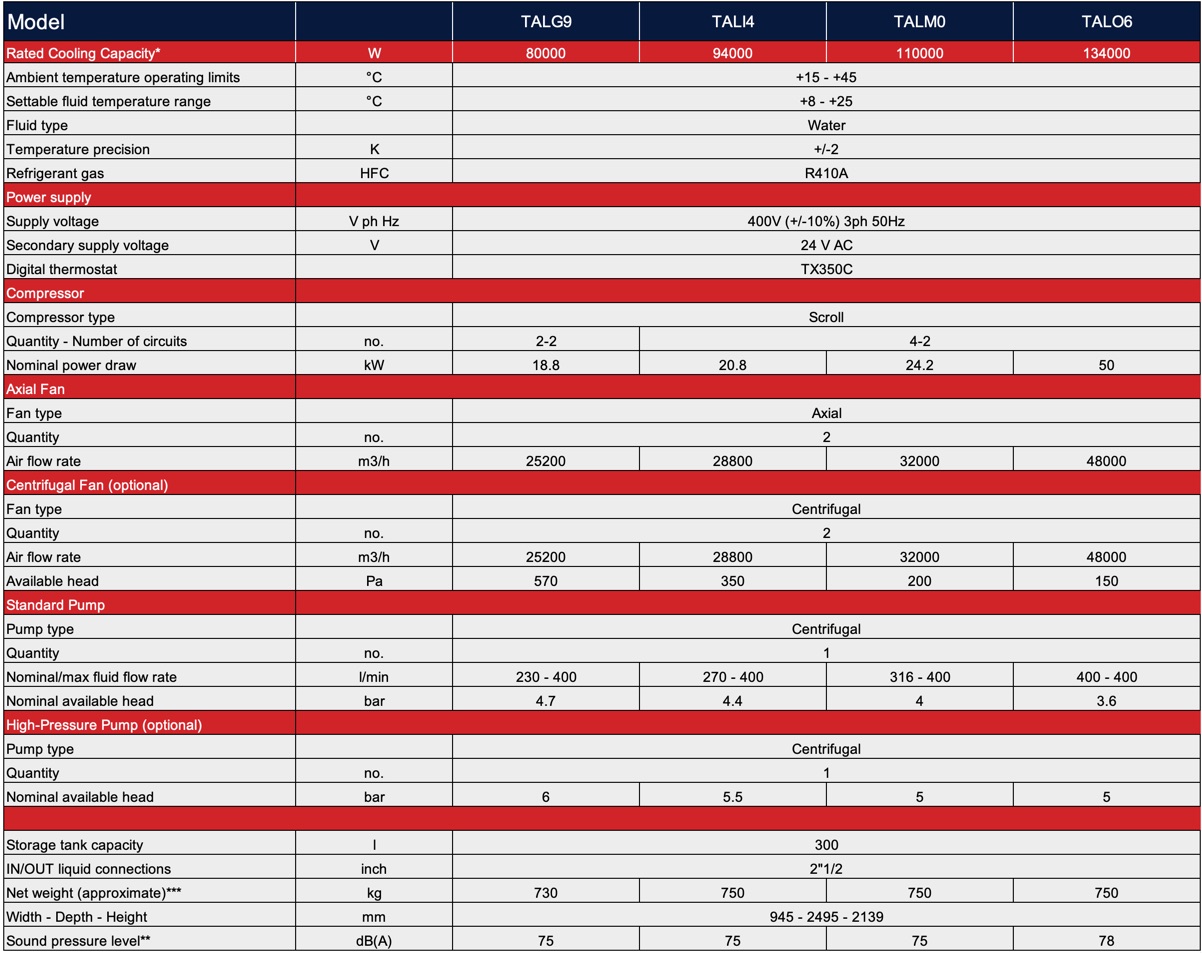

TALG9÷O6 Size 5

Industrial water chillers

COOLING CAPACITY:

80000 – 94000 – 110000 – 134000 W

STRUCTURE

In powder-coated steel sheet, RAL 7035 textured finish. Easily removed panels

COMPRESSOR

Hermetic scroll compressor, cooled by the refrigerant, complete with thermal cut-out.

REFRIGERATION CIRCUIT

Complete with charging port, liquid receiver, drier filter, thermostatic valve, high- and low-pressure pressure switch, R410A refrigerant. Stepped cooling power regulation – 2 steps standard / 4 steps optional (standard on TALO6).

EVAPORATOR

Brazed stainless-steel plate model.

AIR CONDENSER

Microchannel condensing coil, complete with safety grille.

AXIAL FAN

Axial fan, complete with thermal cut-out and safety grille.

LIQUID CIRCUIT

Non-ferrous liquid circuit composed of stainless steel centrifugal electric pump, storage tank made of plastic material complete with drain valve, electrical level indicator, 0-10 bar pressure gauge, differential pressure switch protecting the water flow, automatic by-pass and regulation sensor.

ELECTRICAL PANEL

With main disconnect switch, relay motor protection, phase sequence relays.

MANAGEMENT & CONTROL

The TX350C control unit manages the operation of the chiller and provides complete operator alarm diagnostics. An on-off contact allows the machine to be switched on remotely. Illuminated control selector. RS485 connection. Possibility of remote display for machine regulation.

PAINT/COATING

Standard colour: RAL 7035 textured.

MAIN OPTIONS

FL – Flow switch with alarm contact

HR – Fluid heating element

OM – Unit built for outdoor operation down to -10 °C ambient temp. OML – Unit built for outdoor operation down to -20 °C ambient temp. FP – Polyurethane air filter

TD – Differential fluid temperature management (two sensors)

BGC – Hot gas bypass for +/- 1 K temperature precision

LS – Liquid circuit for laser application

– HIGH-pressure pump version “H” – 5 bar

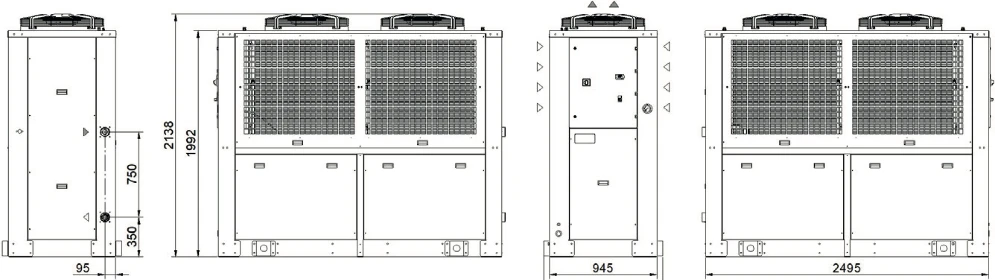

Dimensions

* Data relates to operation under the following conditions: inlet/outlet temp. 20/15°C, water without glycol, ambient temperature 32°C.

** Sound pressure level, measured in a free parallelepiped field at a distance of 1 m, per ISO 3746.

*** Weight includes pallets and packaging (where provided for), with refrigerant charge, storage tank empty, axial fans.

The electrical data refer to cos φ = 0.8.