IT COOLING

Optimised Climate Solutions for Critical Spaces

Vital Technik specialises in IT Cooling equipment, providing top-tier close control air conditioners for data centres and critical environments.

These units ensure precise temperature and humidity control, high energy efficiency, and are adaptable for diverse applications, embodying cutting-edge cooling technology.

Close control air conditioners

Although optimised for data centres, the technical characteristics of the P series units make them ideal for various types of special applications, including: metrology labs, TV production studios, musical instrument recording and storage rooms, museums and archives, control rooms in power stations and railway junctions.

Moreover, they are ideal for use in many industrial sectors: optics, electronics, electromedical devices, electrical or electronic equipment production, musical instrument production, etc.

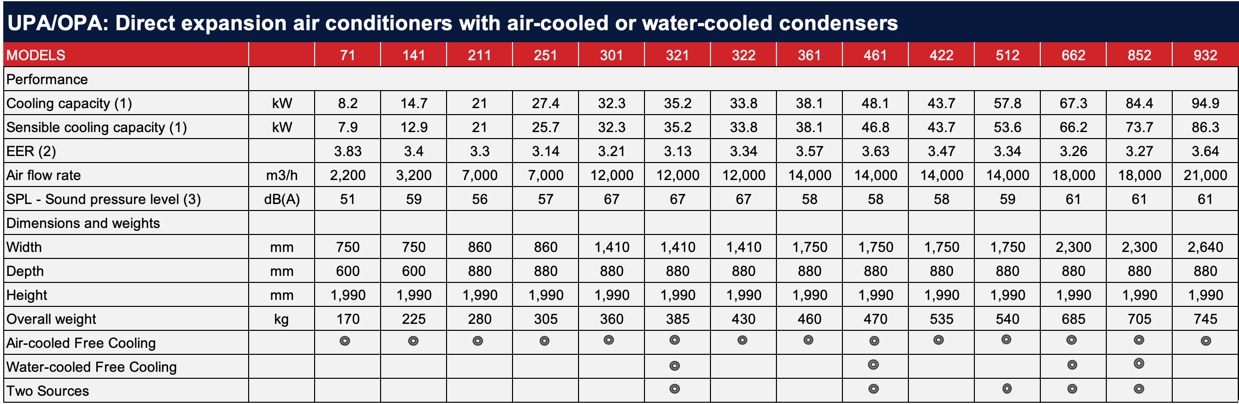

GENERAL SPECIFICATIONS

- Versions with upward and downward air delivery.

- Strict control of room temperature and humidity.

- Very high EER (energy efficiency ratio) and low operating costs.

- High usage flexibility and wide range of accessories.

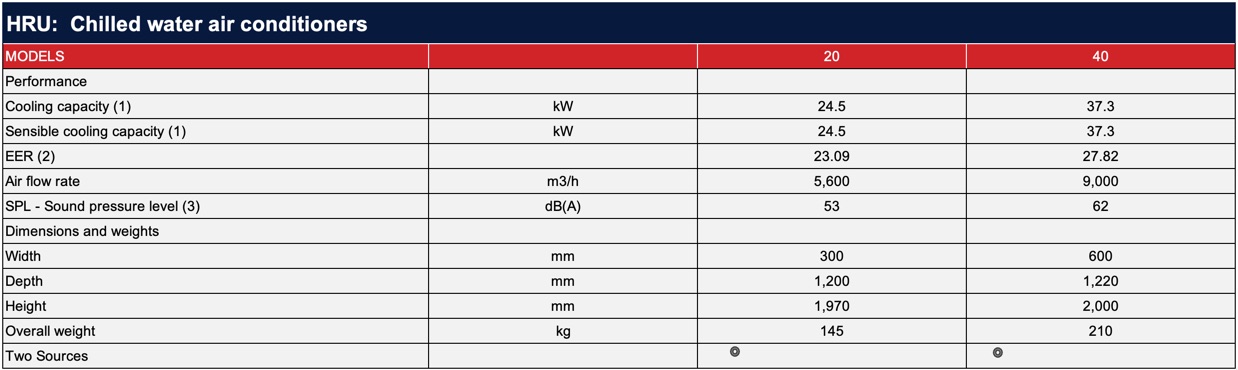

Free Cooling and Two Sources models available

Notes:

(1) Performance refers to: intake air 24°C-45%Rh; R410a refrigerant; condensing temperature 45°C; water temperature 7/12°C; external static pressure 30 Pa. The declared performance does not consider the heat generated by the fans, which must be added to the thermal load of the system.

(2) EER (Energy Efficiency Ratio) = total cooling capacity / input power of compressors + input power of fans (excluding air-cooled condensers).

(3) Sound pressure levels at a distance of 2 m; in a free field; pursuant to UNI EN ISO 3744:2010.

Close control air conditioners for large data centres

In designing air conditioning systems for large data centres, the need to house electrical wires and the enormous quantities of air required to cool the serves has made it necessary to increase the height of the raised floors up to the current 550/1000 millimetres. A large space was therefore created under the air conditioner in which to install the adjustable support. It was then decided to exploit this large space to house the delivery fans without increasing the machine’s footprint, making the most of the available space instead.

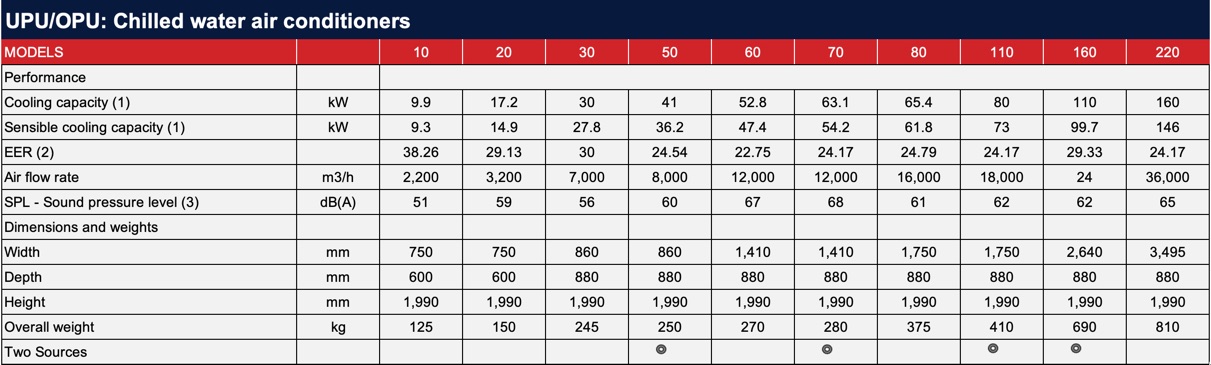

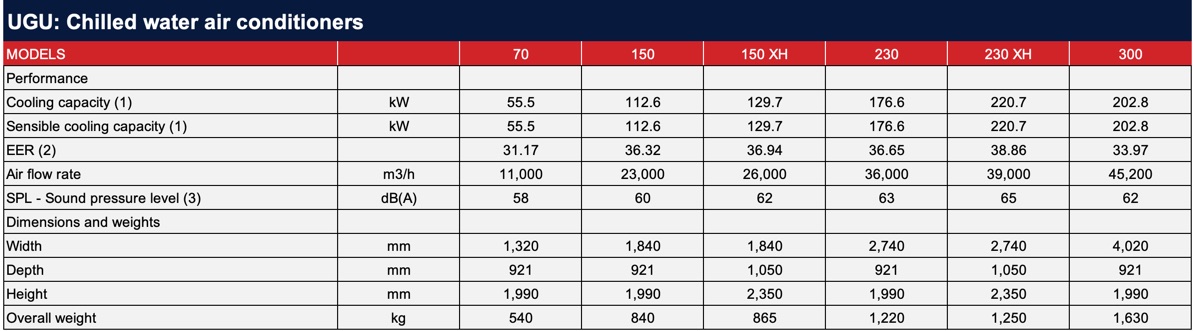

GENERAL SPECIFICATIONS

- Separate air-cooling section for mounting under raised floors.

- High delivered cooling capacity to footprint ratio.

- Optimised air distribution in raised floor.

- Reduced energy consumption of fans.

Chilled water versions available in XH (Extended Height)

Free Cooling and Two Sources models available

Notes:

(1) Performance refers to: intake air 32°C-30%Rh; R410a refrigerant; condensing temperature 45°C; water temperature 12/20°C; external static pressure 30 Pa. The declared performance does not consider the heat generated by the fans, which must be added to the thermal load of the system.

(2) EER (Energy Efficiency Ratio) = total cooling capacity / input power of compressors + input power of fans (excluding air-cooled condensers).

(3) Sound pressure levels at a distance of 2 m; in a free field; pursuant to UNI EN ISO 3744:2010.

Close control air conditioners for installation in service corridors

The W Series units feature constructive and operational characteristics able to satisfy the design criteria of latest-generation large Data Centres in the presence of a technical service corridor. The units are designed to withdraw the warm air generated by the servers, coming from the warm corridor, and blow chilled air directly into the Data Hall.

This type of chilled water unit is specifically designed to be modular and customisable, with a range of possible custom configurations to suit the architecture of modern Data Centres. Its reduced footprint and installation in a service corridor means W Series units avoid occupying critical spaces, thus maximising the capacity of the Data Hall.

GENERAL SPECIFICATIONS

- Technical services corridor mounting.

- No space occupied in the data centre.

- Very high EER (energy efficiency ratio) due to optimised airflow.

- Fully customisable to data centre specifications.

Air conditioners for

“in-row” mounting

In air conditioning systems for large data centres, use of the following design concepts has now become a consolidated practice:

- The racks containing the servers are being increasingly positioned in accordance with the hot corridor (or hot aisle), and cold corridor (or cold aisle) layout.

- The air temperatures are left to rise up to 30-35°C in the hot corridor, and 20-25°C in the cold corridor, with very low humidity (never more than 30%).

- The performance of servers is continually increasing, while their size is getting smaller and smaller.

Many more servers can therefore be installed in one rack, allowing the remaining empty racks to be eliminated. At the same time, the dissipated heat rises, and more power is therefore required of the air conditioners.

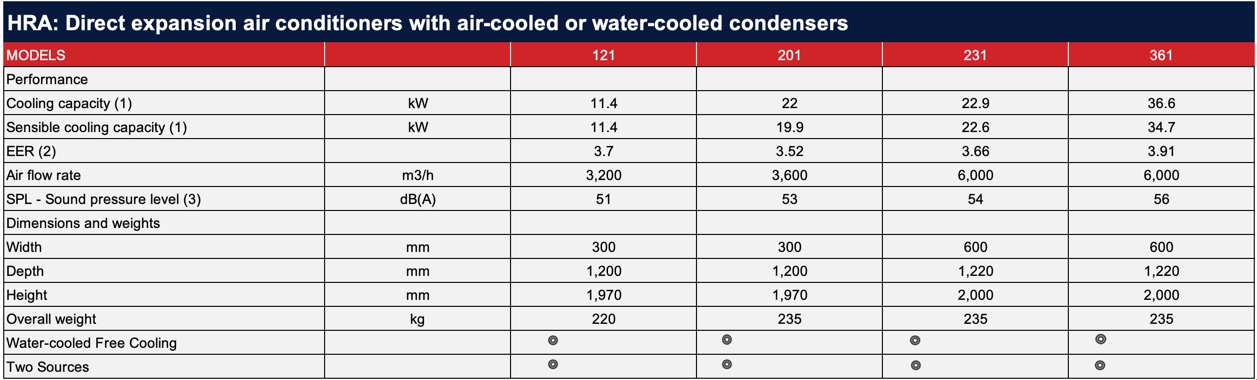

GENERAL SPECIFICATIONS

- Airflow distribution as close as possible to servers.

- Rear suction from hot aisles and front delivery to cold aisles.

- Front and rear access for ease of maintenance.

- Hydraulic, refrigeration and electrical connections from above or below.

Free Cooling and Two Sources models available

H Series AHU's for Operating Theatres; Radiology Bunkers & MRI's

Thanks to twenty years of experience, TECNAIR presents a new generation of H Series air conditioners dedicated to operating theatres and hospitals, where the primary objective is high air quality.

The H Series units, in their standard configuration, are complete with all adjustment components (heat recovery system, cooling, pre- and post-heating, humidification and dehumidification), sized for the treatment of full fresh air or with partial recirculation. A flexible configuration and a high number of accessories guarantee the use of H Series units for applications such as: operating theatres, laboratories and clean rooms, image diagnosis rooms, wards and intensive care.

CHARACTERISTICS

- Compatibility with European Regulation 1253/2014/EU ErP NRVU 2018

- TÜV certification according to DIN1946/4

- Single block painted structure with epoxy resins 60µ RAL 9010

- Panels with thermal and acoustic insulation system using 50 mm thick self-extinguishing material, equipped with handles with safety closing system and inspection window

- Motorised dampers on external air intake and gravitational ones on exhaust

- High levels of static pressure available based on the need for installing absolute terminal filters

- Section for air suction from the rooms, partial recycle or total exhaust to the outside

- Static or dynamic management of overpressure or depression in the controlled room compared to a reference environment

- Room emergency negative pressure activation system

- Three air filtration stages (external, supply and return). Tight seal filter and differential pressure switch supports for each filter

- Easy to sanitise and sterilise. No risk for Legionella Pneumophila

- Condensate drains of the independent sections and fitted with syphon that can be inspected

- Electrical panel complete with adjustment and safety devices

- SURVEYEVO control microprocessor with graphical display

- EC FANS electronic fans

- Hydronic heat recovery system with inverter-controlled pump with thermal by-pass function

- R410A scroll compressors with inverter-controlled brushless DC motor

- Electronic expansion valves EEV with SMART COOL system

- Modulating 3-way/2-way valves

- Anti-freeze safety system

- Submerged electrode humidifier

- Nighttime machine standby and load reduction system for UPS power supply

- RS485 Modbus RTU slave board for interface with BMS (Building Management System)

ACCESSORIES

- Rectangular silencers for duct installation designed for hospital environments and clean rooms

- Motorised dampers on all outlets

- Motorised air recirculation damper

- Execution for external installation

- Modulating two-way valves instead of three-way

- Booster pump with anti-freeze function, for low outdoor temperatures

- Direct expansion post-cooling circuit for cardiac surgery

- System for regulating and distributing network steam

- Constant pressure control in supply and return ducts

- Remote or duct installation room temperature and humidity probes

- Supply humidity probe

- Display system showing the percentage of filter clogging

- User terminal for remote installation

- LED lighting inside the compartments and electrical panel

- Power supply line with speed regulator for remote condenser

- Condensation regulation with 0-10V signal for remote condenser with EC fans

Notes:

(1) The performances, declared according to UNI EN 14511-1:2018, do not consider the heat generated by the fans which must be added to the thermal load of the system. The performances refer to the following conditions: incoming air: 35°C-40% UR; heat recovery with glycol at 27%; water: 7/12°C.

(2) The performances, declared according to UNI EN 14511-1:2018, do not consider the heat generated by the fans which must be added to the thermal load of the system. The performances refer to the following conditions: incoming air: 35°C-40% UR; heat recovery with glycol at 27%; R410a coolant; condensation temperature: 45°C.

(3) External static pressure: 800 Pa.

(4) The sound pressure levels at a distance of 2 m, 1.5 m height, free field and with ducted supply outlets, declared according to UNI EN ISO 3744:2010.

(*) Direct expansion execution (OHA) only.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.